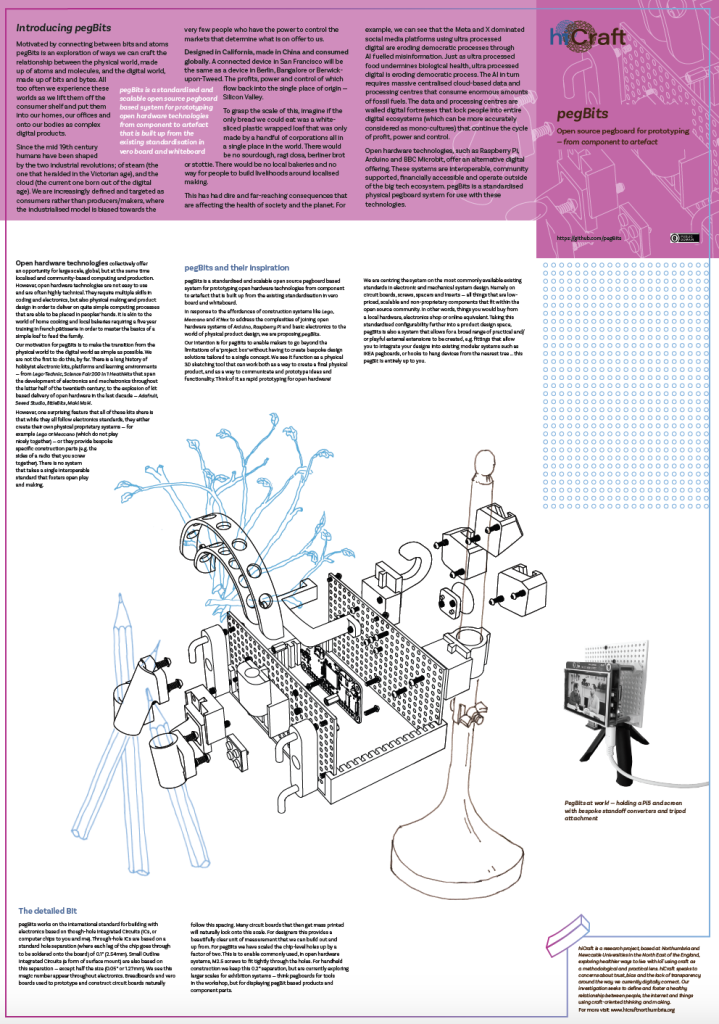

pegBits – Jon Rogers & Justin Marshall

What are pegBits?

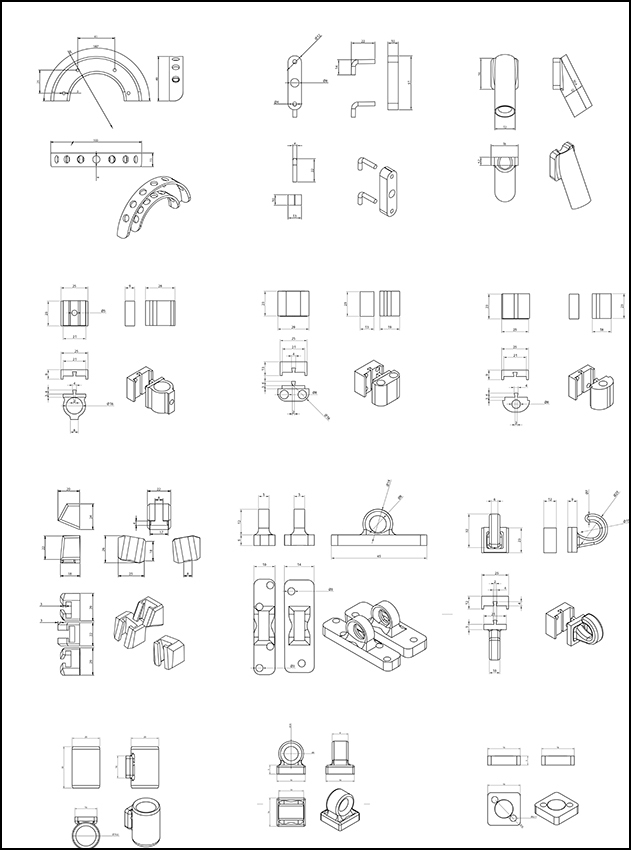

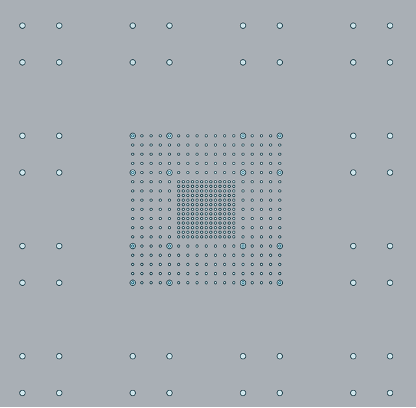

PegBits is a standardised and scalable open source pegboard based system for prototyping open hardware technologies from component to artefact. It works on the international standard for building with electronics based on though-hole Integrated Circuits (ICs). Through-hole ICs are based on a standard hole separation of 0.1” (2.54mm). PegBits are centred around the most commonly available existing standards in electronic and mechanical system design, namely on circuit boards (e.g stripboard), screws, spacers and inserts — all things that are low-priced, scalable and non-proprietary components that are commonly used within the open source electonics community. So pegBits seek to integrate physical computing into the physical world akin to how Meccano or Lego afford adaptation and construction through utilising standardisation and constraints.

Where did pegBits come from?

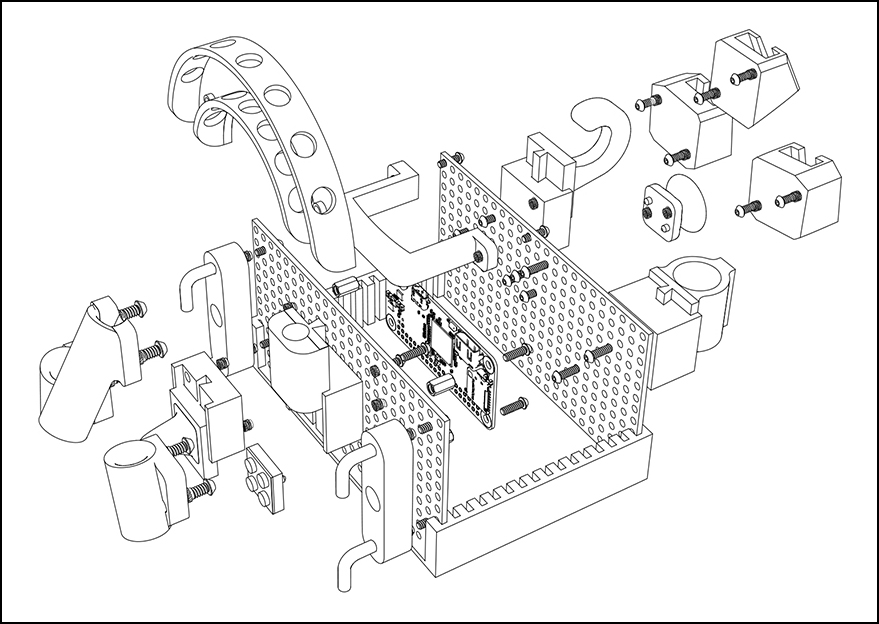

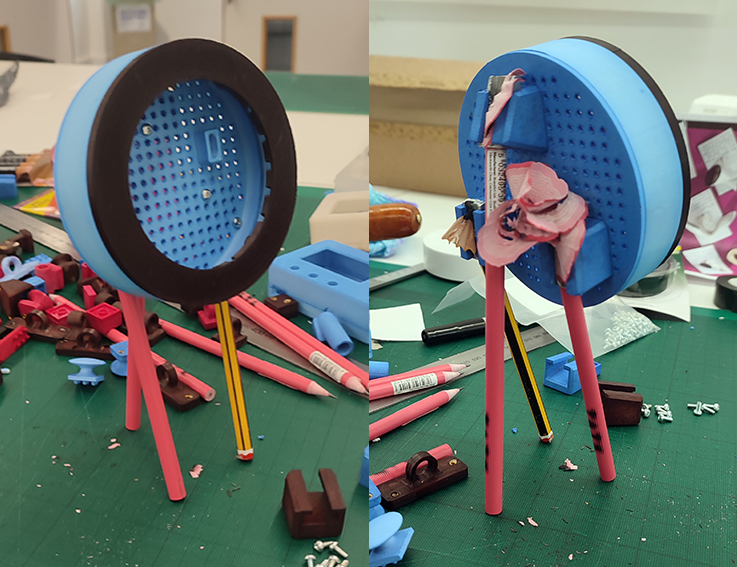

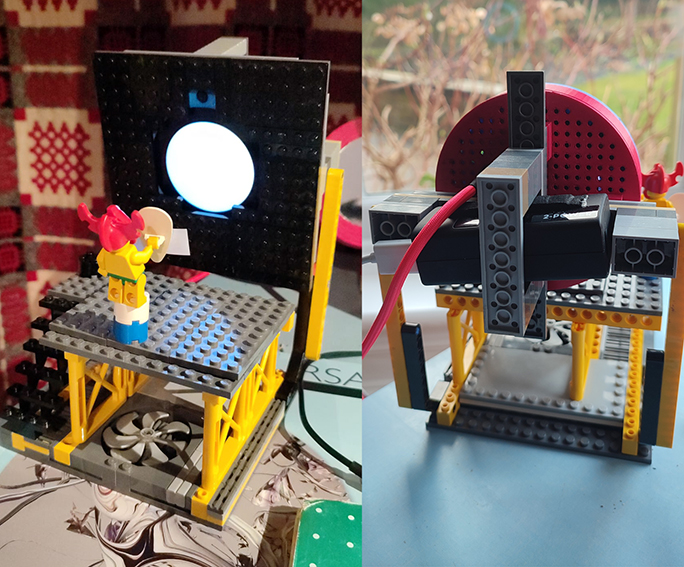

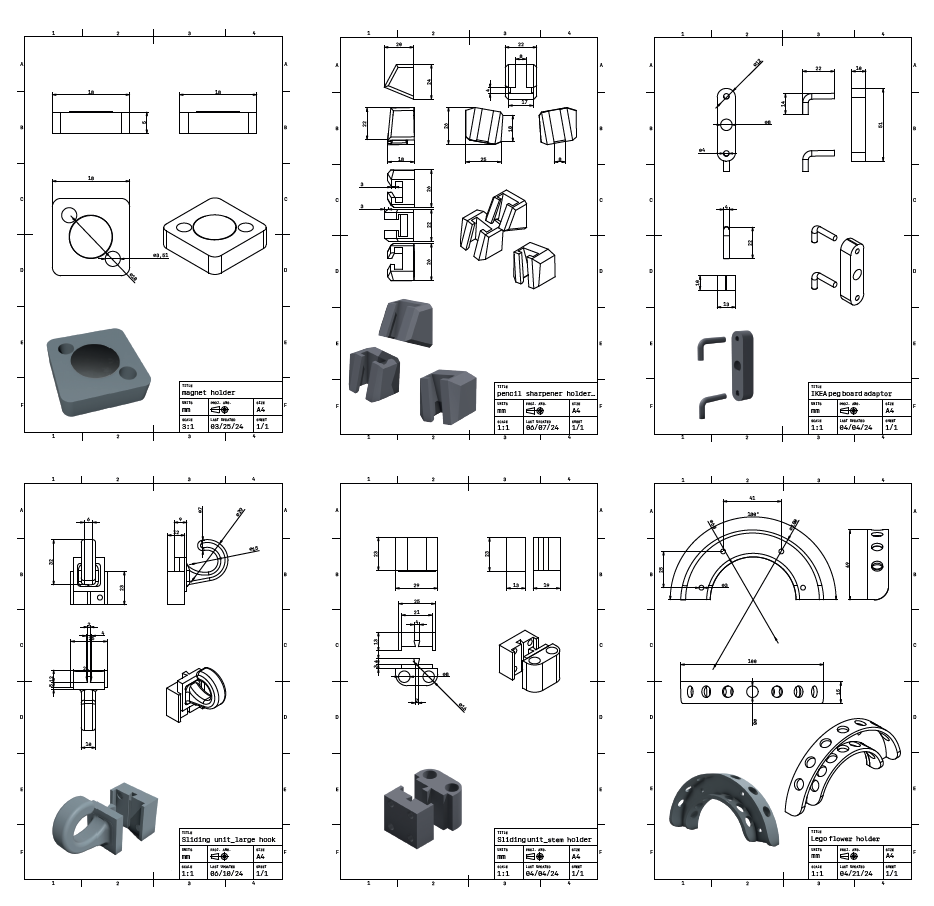

Motivated by connecting bits and atoms we developed pegBits as an exploration into ways we can craft the relationship between the physical world, made up of atoms and molecules, and the digital world, made up of bits and bytes. We first explored this concept through the hiCams project where we used a 0.2” hole spaced grid (i.e. 0.1” x2) in the back plate as both a ventilation for the electronics and as base onto which a variety of pegBits components could be attached. We developed a range of hooks, eyelets, brackets and other attachment designs; some practical, some less so and some just playful! (E.g. Ikea peg board mounting brackets, pencil sharpener adjustable leg holders, sleeves to hold twigs and branches etc.) We were keen to create opportunities for the personalisation of our hiCams and/or to leverage our craft skills to create sense of ownership. So although the 3D printed pegBits are standardised and conform to a digital industrial design aesthetic they facilitate the creation of forms that have distinctly different look and feel, emphasising bespokeness and materiality – they seek to bridge analogue and digital worlds in a craft-oriented way.

Developing 1st iteration

Our first attempt at fixing the pegBits to the hiCams backplate involved studs modelled into the back face of the peg Bits. Though this facilitated very quick reconfiguration it proved not to be robust or secure enough for most applications and we finally used standard M2.5 screw bolts and brass inserts, which is very robust and also fits better with the underlying pegBits ethos to standardisation and compatibility across electronic platforms and the fixing they use.

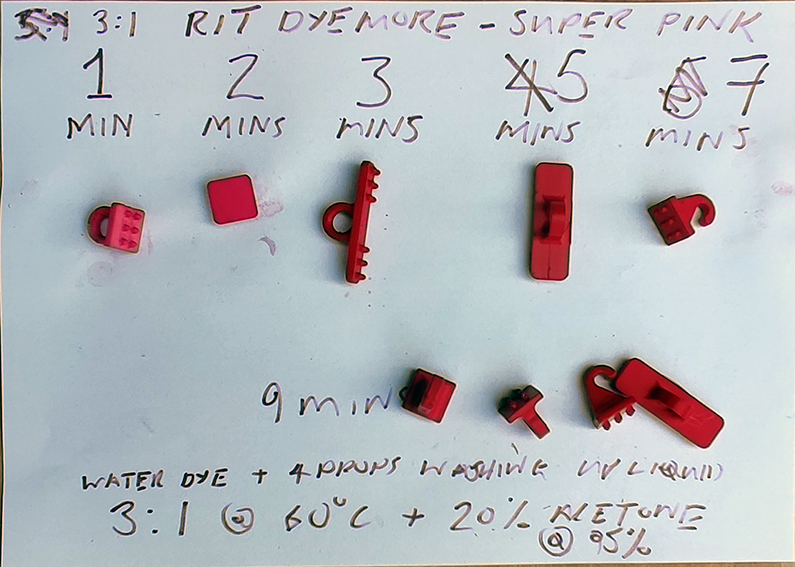

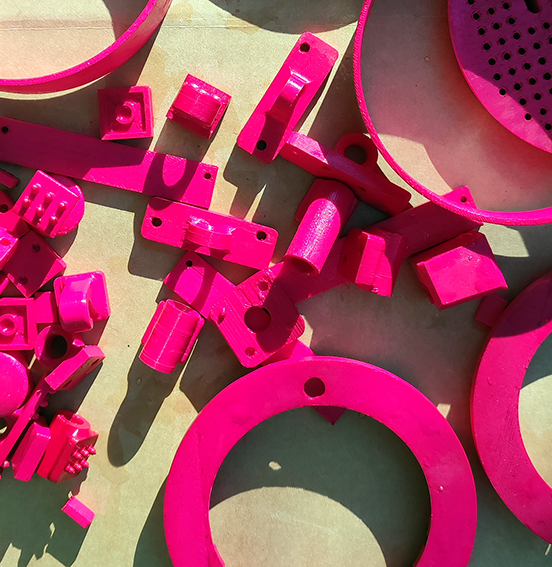

To further emphasise the importance of the material qualities of the pegBits (and the hiCams more broadly) we investigated ways to create richer and less uniform surfaces through dying items rather than using the limited (and bland) set of PLA filament colours available for 3D printing. This did provide some interesting results, though surprisingly variable across the hiCraft colour palette, magenta being the most striking! Though appealing this strategy was replaced with off the shelf coloured PLA in further iterations as not only did it provide consistent (if less interesting) colour, it also reduced the small variabilities in scale that dye the pieces created, which had the knock on effect of making the hiCams friction fit design less reliable.

Scaling up

The underlying principle of scaling by factors of 2 was taken further in the exhibition system we developed for our V&A exhibition and workshop. CNC milled laminate panels we created used a 0.2” spacing (0.1”x 2) as the initial grid spacing, then a 0.4” space grid (0.2”x2) to create a display space for pegBit attachments, and finally a combined 1.6” and 3.2” grid (0.4”x2x2(x2)) for shelf and other forms of larger brackets used to hang exhibition pieces and fix cabling. This doubling approach to scaling can be found in many contexts, from the “A” sizing of paper stock (two A4 sheets fit into one A3 sheet), to the way Lego unit scale (two 4 pin Lego bricks fit into one 4 pin Duplo block), and provides a simple legible logic while also allowing scaleable modularity.

2nd iteration & further developments

The pegBits concept is in the process of further development in order to create a more flexible and modular systems based on the 0.1″ grid and scaling by powers of 2. More info on this will be shared in February 2025. See https://github.com/pegBits for a growing repository of files and information.